The KUZ is development partner for custom-fit plastics technology solutions. At Fakuma from October 17-21, the focus will be on sustainable products and optimized processes. At its booth, the research institute will provide insight into future topics for various industries.

Precise and at the same time large-scale micro injection molding on conventional machines is possible thanks to the new "Scale-Mi" technology. The solution: The plasticizing unit of a small conventional injection molding machine feeds a melt distributor in a mold plate as a metering unit. From this, coupled micro-injection units actively inject into a high-cavity mold. The combination of individual cavities to form a family mold and thus the production of different molded parts in one shot can also be realized with the new technology, thanks to variable setting parameters of the individual piston drives and coordination of the shot volumes.

KUZ presents an AI-supported system for online dosing of liquid colors in the injection molding process. With the automated process, the effort required for coloring molded parts during injection molding can be greatly reduced and product color consistency can be realized even with fluctuating material properties. Small batch sizes can be offered profitably and thus individual flexible solutions can be realized. Using the demonstrator, visitors can learn about the process of AI-supported metering of liquid colors at the trade show booth.

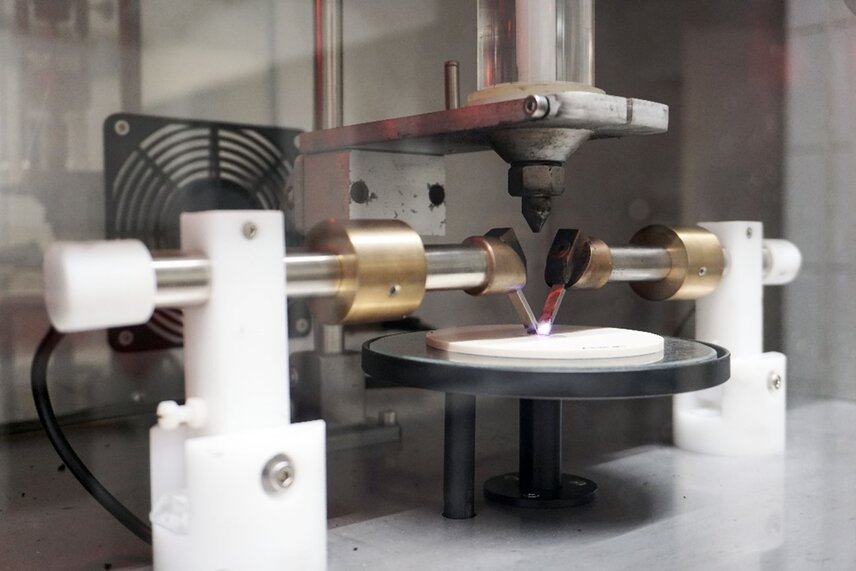

Plastics are increasingly used as insulators in high-voltage applications, such as electromobility. For testing the tracking resistance (CTI) value, the recommended voltage according to DIN EN 60112 is up to 600 V. Problem: This value is often insufficient for the intended applications. The accredited test laboratory of the KUZ works with a new type of CTI test device with an extended voltage range up to 950 V and can thus meet current requirements more effectively. For example, current applications from electromobility can be designed with pinpoint accuracy or charging infrastructures can be tested more reliably.

The KUZ is at the Fakuma trade show booth with its mobile "RecyclingDay" bicycle and related equipment. Here, visitors can injection mold new toys and useful helpers from old bottle caps in a "Do It Yourself" manner. Outside the trade show, the "RecyclingDay" project serves to promote young talent and impart knowledge to schoolchildren on the subject of recycling and the sustainable use of plastics as a valuable material.

Precision Molding Excellence: Accumold, the forefront innovator in micro injection molding, will showcase cutting-edge capabilities at SPIE Photonics West from …

IVAM member Micro Systems is proud to celebrate its 20th anniversary of precision engineering excellence in mold design, mould manufacture …

The ZIM innovation network “Poly4Nature - Alternative Raw Materials and Natural Polymers” has successfully entered its second phase. The aim …