Filling electrolytes into battery cells is a critical step in battery manufacturing. Factors such as electrolyte formulation, pressure and temperature must be considered in the filling process. Critical to battery performance and life are the quality of the electrolyte and the accuracy of the filling process. Small dispensing errors cause large variations in performance. High-precision micro annular gear pumps from HNP Mikrosysteme are used for this application.

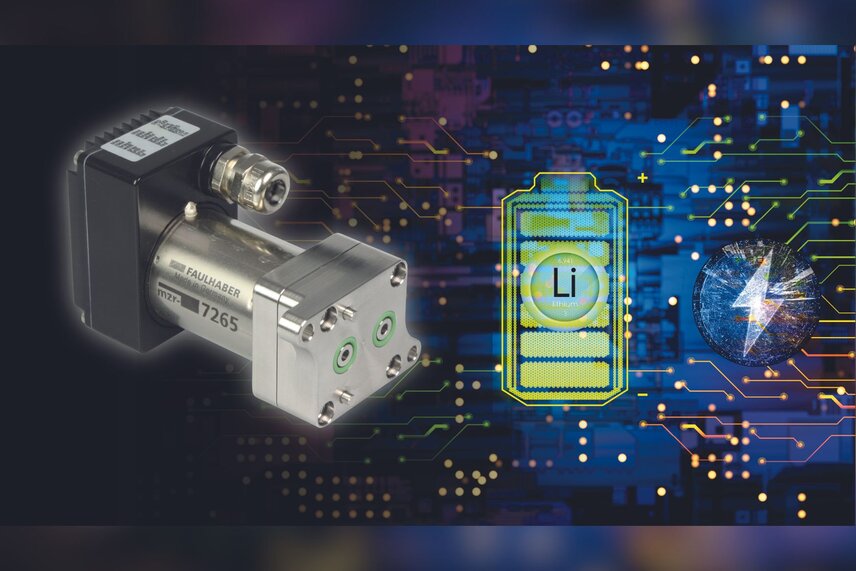

Lithium-based liquid battery electrolytes are crystallizing and hazardous to health, and require the use of hermetic pumps. The magnetic hermetic pump mzr-7265 doses volumes between 4 and 8 ml in 2 seconds with a deviation of less than 1%. The process takes place under vacuum conditions. In addition to low-pulsation and precise dosing, the pump realizes very short cycle times.

LOHC-based hydrogen storage is another application field for micro annular gear pumps. Pumps of the high performance series, mzr-4605 or mzr-7205 are used to deliver LOHC dibenzyltoluene, also known as Marlotherm, perhydro-dibenzyltoluene and benzyltoluene. For example, the pumps deliver dibenzyltoluene with volume flow rates between 1 ml/min and 240 ml/min into a reactor. Here, the medium is charged with hydrogen by means of hydrogenation.

Contact: Dörte Hoffmann, HNP Mikrosysteme

doerte.hoffmann@hnp-mikrosysteme.de

In a time of challenges related to finite resources and increased demand to reduce the overall carbon footprint, smart features …

Anodic Arc Evaporation: A Key Enabler for Next-Generation Photovoltaics: The EU-funded LUMINOSITY project unites 15 research and industry partners from …

Cancer diagnostics is at a turning point: new technologies are fundamentally changing how we recognize, understand and treat diseases. This …