Favorite (5)

Favorite (5)

Microfluidic technologies can be used in a variety of ways and applied in various fields, including chemical microreactors for production, bioanalytical lab-on-a-chip devices, micropumps and inkjet print heads.

At this point, we would like to give you a brief overview of what the exhibiting companies and institutes at COMPAMED will show you in the field of microfluidics.

HNP Mikrosysteme produces micro annular gear pumps.

These pumps are ideally used where fast and highly precise dosage is required.

Five series guarantee a flow rate from 1 µl/h to 1152 ml/min. mzr-pumps are characterized by low pulse delivery, minimal dead volume, long service life, small dimensions, powerful materials and ease of maintenance.

The company offers the development of OEM pumps, comprehensive application-specific consulting and technical support. Application possibilities amongst others are in the field of life science and analytical instrumentation.

IMT Masken und Teilungen AG develops microfluidic chips and flow cells for tomorrow's biotechnology and offers flexible process offerings from design consulting to prototyping to scalable manufacturing.

IMT specializes in complex glass microfluidic components facilitating for multiplexing, accurate position of analytes, increased signal to noise, decreased fallout rate, exact dosage of extremely small volumes.

The products are used in the areas of NGS flow cell, organ-on-a-chip, lab-on-a-chip, single-cell analysis, cell enrichment and sample preparation.

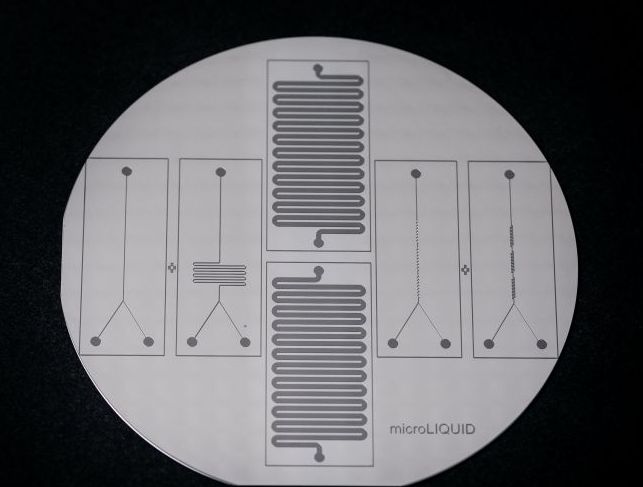

microLIQUID’s experienced NPD/NPI team take products all the way from product development to small- and large-scale manufacturing.

The applications range from point of care at hospitals, immunoassay tests at veterinary clinics, single-cell analysis systems at the world’s leading cancer R&D centers, to even personal drug delivery devices at local pharmacies, and automated systems at IVF clinics.

Micronit is a key supplier of microfluidic and MEMS components for applications in life science research, medical devices and in-vitro-diagnostics worldwide and has been manufacturing these products for more than 15 years.

Micronit’s lab-on-chip and MEMS solutions are used in areas like genomics (e.g. next-generation sequencing), single-cell analysis, point-of-care diagnostics, organ-on-chip and cell culturing, drug delivery, and medical MEMS-based devices.

Micronit has extensive experience in microfabrication technologies used for prototyping and volume manufacturing of microfluidics and MEMS products.

TTP Ventus introduces the award-winning Disc Pump range, which are enabling innovation in portable and wearable devices across the medical and life sciences sectors. The pumps deliver high pressure and flow, silent operation, pulsation-free flow, millisecond response time high-precision controllability – all in a tiny package.

The pumps are suitable for applications spanning blood pressure monitoring, capnography, compression therapy, vacuum prosthetics, thoracic drainage, MRI compatible instruments, point-of-care diagnostics and microfluidics.

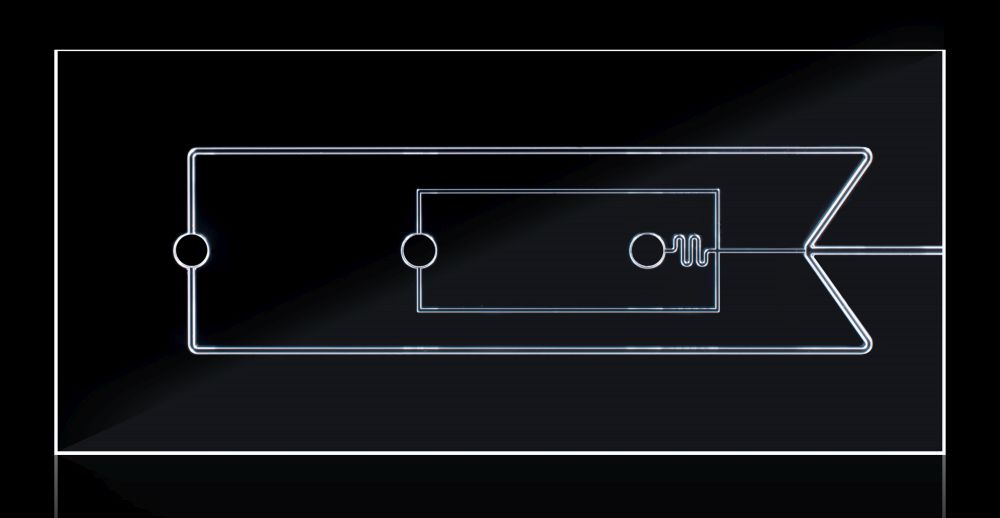

Micro Systems UK Ltd. will be displaying microfluidic droplets and distribution components at the fair.

The company utilizes its knowledge and experience in micro manufacturing to demonstrate a micro production mold which has two components, one to produce a droplet generator and a second to produce a mixing manifold for generating water-in-oil droplets or oil droplets in-water.

The microfluidic component incorporates 150x150 micron channels with a mixing chamber of 50x50 microns. Any microfluidic design within the micro function area can be incorporated.

At COMPAMED, CG.TEC Injection will demonstrate its know-how in the field of microfluidics, e.g. for lab-on-a-chip applications. The injection is made in a clean-room ISO 7 (class 10 000) with a wide range of polymers (COC, PS, PC, TPX, PEEK…). The cartridge template is up to 100x80mm, detail size down to 7 μm and radius down to 1.3 μm. Additive 3D manufacturing allows a complete "Atelier Dedienne 3D" for the mass production of functional parts.

VICI AG International presents an entire chromatographic system in a small 6x6'' footprint. With True Nano 360 μm fittings, flow rates as low as 10 nL/min, and pressure up to 1500 bar (22000 psi), this system provides split-free injections as close to the detector as possible.

This allows the use of high efficiency columns, packed with micro particles for an order of magnitude increase in theoretical plates and plate height. Pump options include single and multiple pump configurations as well as isocracy and gradient options. Each pump head has an integrated pressure transducer to monitor and adjust a solvent.

If you are interested in sharing knowledge and discussing common problems with regard to research, development, manufacturing and selling of microfluidic products, please contact the "IVAM Focus Group Microfluidic" via microfluidics@ivam.de .