Favorite (3)

Favorite (3)

These properties together with the mechanical specifications regarding hardness, Young’s modulus and high isotropy degree make glass an interesting choice for many medical, scientific, and industrial applications where high levels of precision and durability are required.

Sometimes classic machining technologies as grinding or cleaving can leave stress or sub-surfacedamage, however there is a new machining technology is able to overcome the aforementioned disadvantages.

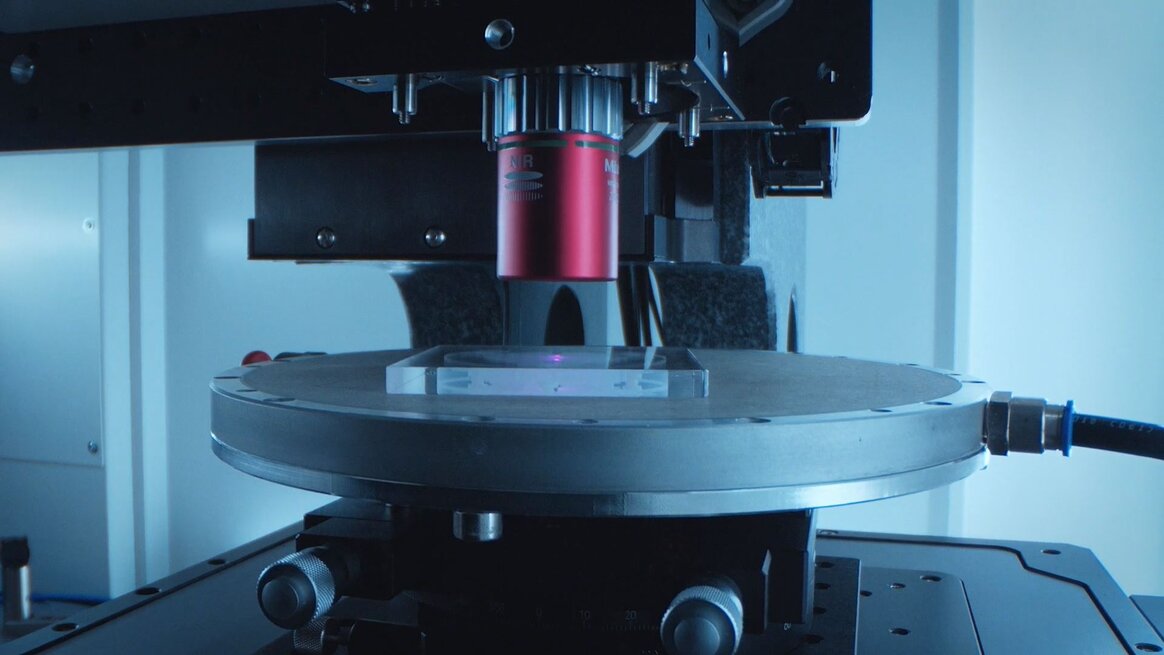

Selective Laser-Induced Etching (SLE) is a new technology that enables production of complex 3 dimensional structures from dielectric materials such as glasses, crystals & semiconductors, that are transparent to the wavelength of the laser radiation that is being used.

The SLE process comprises of a combination of spatially selective material modification by means of laser radiation and subsequent removal of only the afore-modified material by wet-chemical etching.

SLE opens up a new way to micro-functionality making it possible to integrate a wide range of optical, mechanical, and fluidic functionalities inside devices. Some of the most demanded SLE applications include injection nozzles, MEMS, smart implants, sensors, microfluidic devices, cell-sorting and - analysis etc.

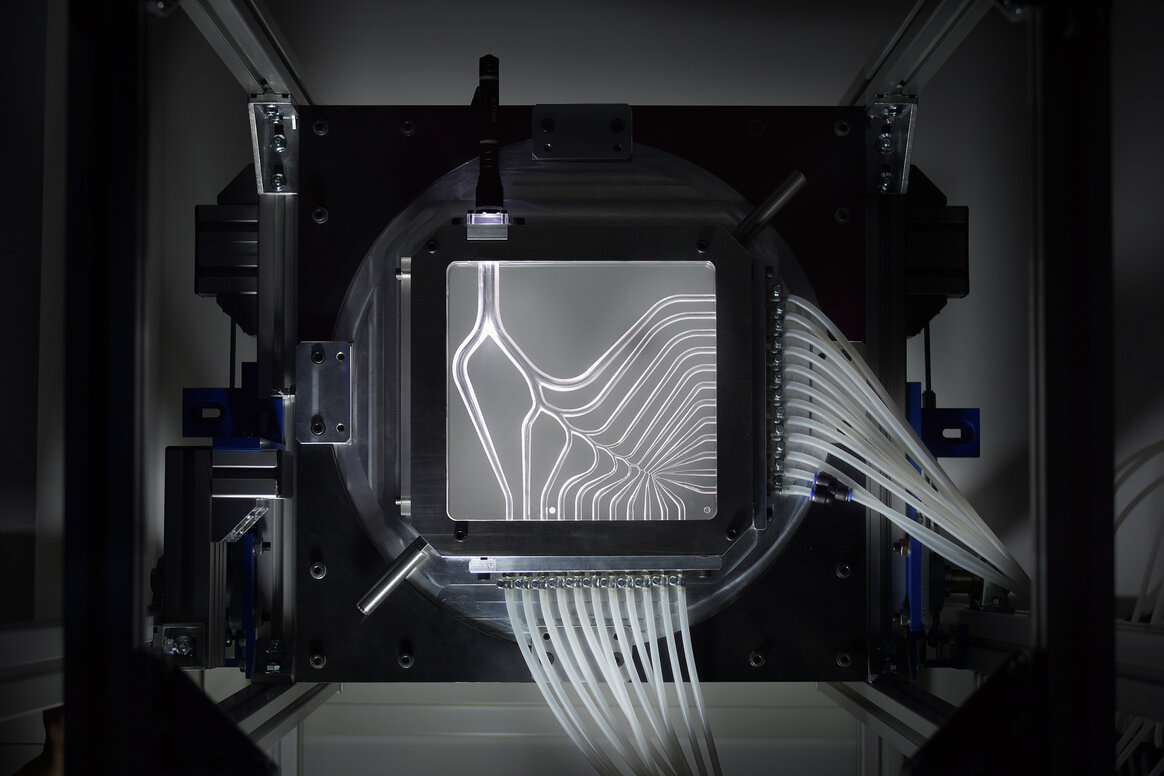

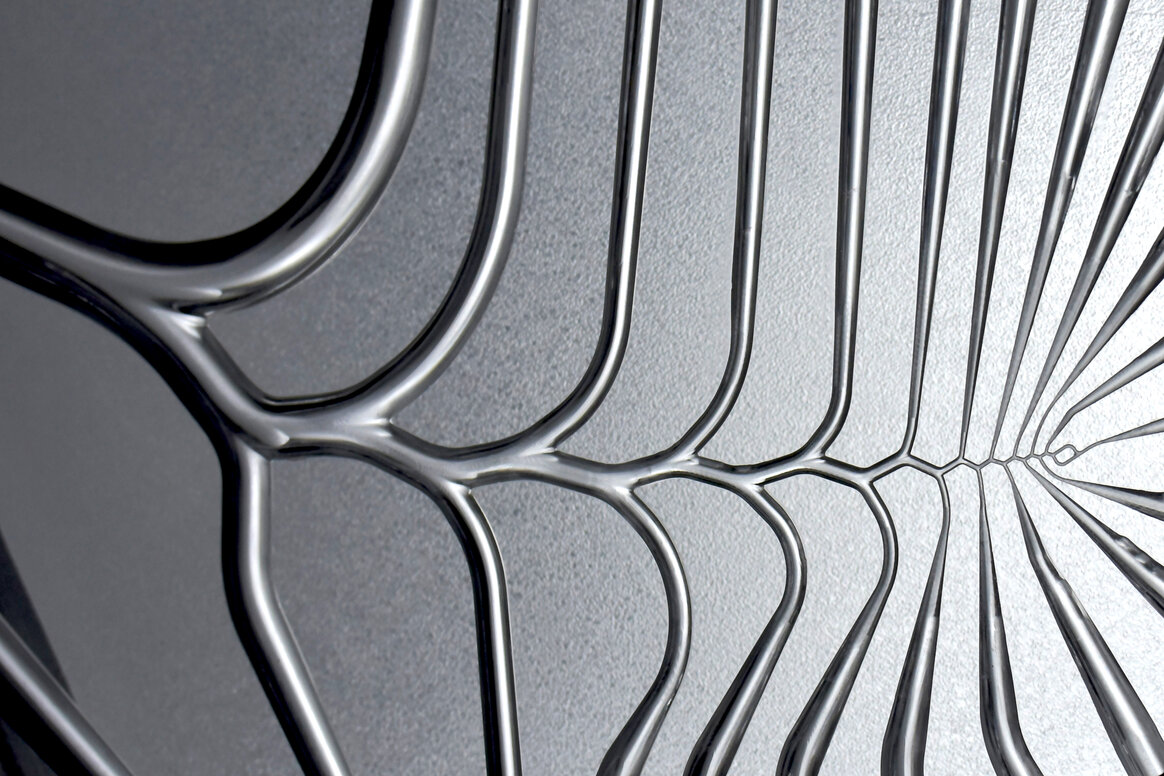

LouwersHanique together with LightFab GmbH and in co-operation with RWTH Aachen University, has created a human lung that enables the development of new experimental aerosol therapeutic techniques. A unique combination of fabrication techniques was used to remove quartz inside the model, including 5 axis CNC milling, polishing, and the previously mentioned SLE (Selective Laser- induced Etching).

The glass lung was bonded out of two transparent fused silica plates, which made the application of different optical measurement techniques possible to analyse aerosol propagation and deposition on a microscopic level e.g. how deep stem cells can get into the lungs for therapy purposes. In addition, this technology enables to individually adjust and measure the pressure for each of the 23 bifurcation units of the lung allowing to simulate specific human breathing characteristics.

In summary, the glass lung created through Selective Laser-Induced Etching technology offers a glimpse into the limitless potential of precision manufacturing techniques in the medical and scientific field.

LouwersHanique is a contract manufacturer that develops and manufactures high precision components and sub-assemblies made of technical glass, ceramics and other brittle materials. This includes full support throughout the lifecycle of a project from concept, engineering, machining, assembly and UHV cleaning to production and quality control. LouwersHanique works on mission critical components that make a difference in high tech applications for customers in the semiconductors, medical and life science industry. Discover more about our technical solutions in glass and ceramics in our website www.louwershanique.com

LouwersHanique BV, Hapert, Netherlands

https://www.louwershanique.com/